The European potato sector sits at the intersection of traditional farming and modern food systems, reflecting a complex interplay of agronomy, market forces and policy. This article examines the drivers of profitability for potato producers across different regions of Europe, drawing attention to the most influential cost items, revenue streams and strategic choices that determine farm-level outcomes. By exploring production systems, value chains and emerging trends, the discussion aims to equip stakeholders — farmers, agribusinesses and policymakers — with practical perspectives for making resilient and profitable decisions.

Market structure and demand dynamics

Understanding where revenue comes from is essential to assessing profitability. In Europe, potatoes serve three main markets: fresh consumption, processing (primarily chips and fries), and industrial uses such as starch and seed production. Each segment has different price structures, quality requirements and contract arrangements. Fresh markets are sensitive to consumer preferences, seasonality and retail promotions; processing buyers often demand specific varieties and consistent supply; industrial buyers value uniformity and long-term contracts.

Price formation and volatility

Potato market prices are shaped by seasonal gluts and shortages, stock levels, international trade flows and input cost changes. For many producers, short-term price shocks—driven by adverse weather in major producing regions or sudden shifts in energy prices—can sweep away narrow margins. Futures markets are limited for potatoes compared to cereals, so price risk is often managed through forward contracts with processors and retailers, or through membership in cooperatives that can smooth returns.

- Fresh market premiums depend on size, appearance and local consumer demand.

- Processing contracts usually specify varietal and tuber specifications, and sometimes offer premiums for higher dry matter content.

- Seed potato markets command higher prices but require strict phytosanitary standards and certification costs.

Cost components, yield drivers and farm-level economics

Profit margins in potato production are a function of gross margin per hectare and fixed cost allocation. Key cost components include seed tubers, fertilizer, crop protection, fuel and machinery, labour, irrigation, and post-harvest handling. Among these, the cost of seed tubers and crop protection chemicals can represent a significant share of variable costs, especially for high-yielding, high-input systems.

Yield as the central revenue lever

Yield variability is a major determinant of revenue. Achieving high and stable yield depends on variety choice, soil health, pest and disease management (notably late blight), planting date and density, irrigation capacity, and effective nutrient management. Yield improvements translate to better fixed-cost absorption and higher net returns, but they may require higher input intensities.

Examples of major cost shares

- Seed: 15–30% of variable costs, depending on whether certified seed is used.

- Crop protection: 10–25%, linked to disease pressure and integrated pest management (IPM) adoption.

- Fertilizer: 10–20%, influenced by soil fertility and precision application technologies.

- Labour and machinery: 20–35%, depending on mechanisation level and scale.

Given these shares, farmers aiming to improve margins can either reduce costs (e.g., through mechanisation, optimized agronomy, or cooperative procurement) or increase revenue per tonne (through quality premiums, better storage and timing of sales, or vertical integration with processing).

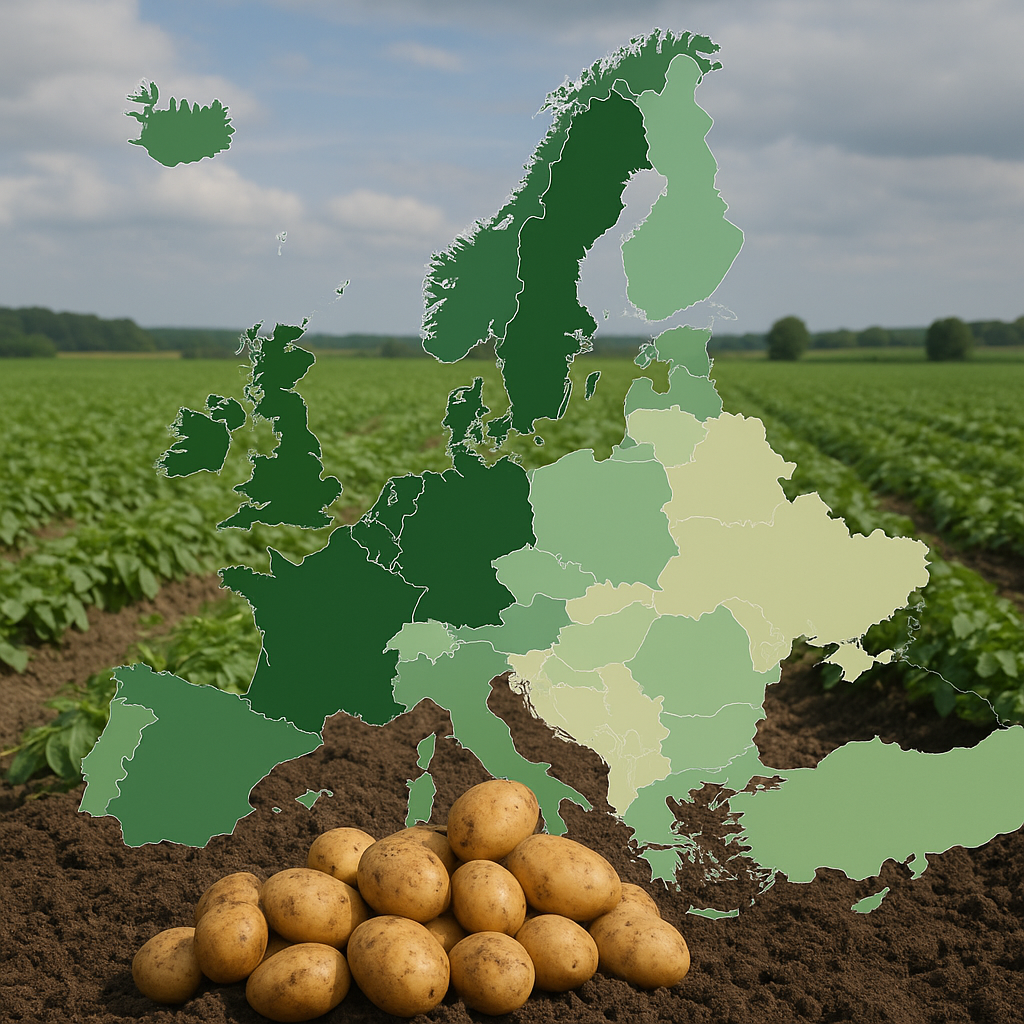

Regional differences across Europe

Europe is heterogeneous in terms of climate, farm structure and market orientation, and these differences materially affect profitability. Western and Northern Europe tend to have higher input costs and labour rates, but more developed processing industries and stricter quality standards. Eastern and Central Europe often offer lower variable costs and larger area potential, but face challenges in access to capital, mechanisation and stable market channels.

Western and Northern Europe

Countries such as the Netherlands, Belgium, Germany and the UK are characterized by high-intensity, technology-driven production systems. The Netherlands combines high yields with strong processing and export networks. In these regions, economies of scale, precision farming and strong grower-processor relationships support margins despite high labour and land costs.

Eastern and Central Europe

In parts of Poland, Romania and the Baltic states, potato production remains more diversified among smallholders and medium farms. Lower land and labour costs can generate competitive per-tonne production costs, but limited access to certified seed, storage and processing contracts can constrain returns. Investment in supply chain consolidation and improved storage could unlock higher margins.

Southern Europe

Warmer climates and differing water availability make irrigation and variety selection central concerns. Southern producers may face higher risk from drought and heat stress, which influence both yield and tuber quality. Niche markets for table potatoes and local varieties can boost farm incomes where supply chains capitalize on regional identity.

Value chain, processing and post-harvest management

Margins are not determined solely by field-level performance. Post-harvest handling, storage and processing orientation are decisive. Investment in controlled-atmosphere storage or modern washing and grading facilities enables better timing of sales and access to higher-value markets. Processors often pay premiums for predictable supply and specified tuber characteristics, which increases the attractiveness of contract production.

Storage economics

Effective storage reduces seasonal gluts and allows sellers to obtain higher prices during off-peak months. However, storage incurs costs—capital, energy for cooling and ventilation, and quality management. The decision to invest depends on expected price spreads between harvest and lean months and the farmer’s capacity to manage post-harvest risks such as sprouting and disease.

- Short-term cold storage is suited to fresh-market producers seeking quality retention.

- Long-term controlled storage benefits large-scale packers and contract growers who can spread fixed storage costs over volume.

- Collective storage schemes can improve returns for smallholders by pooling volumes and costs.

Policy, risk management and sustainability

Public policy, especially the Common Agricultural Policy (CAP), influences the sector via direct payments, environmental schemes and rural development funds. Subsidies can support structural investments like storage or irrigation and incentivize sustainability practices that have long-term benefits for soil health and market access. Environmental regulations (e.g., restrictions on certain pesticides or nutrients) may raise short-term costs but can create market opportunities for low-input or eco-labelled potatoes.

Climate change and integrated pest management

Warming temperatures and shifting precipitation patterns alter disease pressure and growing seasons. Investment in resistant varieties and technology for monitoring (drones, sensors) can reduce risk and improve input efficiency. Integrated pest management (IPM) reduces reliance on chemical controls and can lower costs while meeting retailer and regulatory standards.

Financial instruments and contractual solutions

Because potatoes have limited futures markets, other instruments help manage price and production risk: forward contracts with processors, crop insurance schemes where available, and membership in cooperatives that negotiate prices and provide access to credit and inputs. Farmers who secure multi-year contracts with processors can often justify investments in quality-enhancing practices because of predictable demand.

Technological and business innovations improving margins

Modern approaches that can raise profitability include precision nutrient management, GPS-guided planting and harvesting, automated grading, and digital marketplaces that improve price discovery. Innovations in variety breeding — for higher yield, disease resistance and storage life — also change the economics by lowering input needs or increasing the portion of produce that meets premium specifications.

- Precision application of fertilizer and pesticides reduces input waste and cost.

- Mechanised planting and harvesting cut labour costs and improve timeliness.

- Traceability systems and certification open access to higher-value export and organic markets.

Strategies for improving farm-level returns

Practical approaches to increase net returns often combine agronomic improvements with market strategies. Key tactics include: focusing on varieties that match market demand; negotiating forward contracts or joining cooperatives to reduce price risk; investing selectively in storage and graded packing to capture seasonal premiums; adopting precision tools to reduce input costs; and pursuing product differentiation through quality, regional branding or diversification into processing lines or direct consumer sales.

Checklist for managers and advisors

- Conduct a whole-farm margin analysis to identify where per-hectare profit is lost.

- Benchmark input costs and yields against regional peers to spot improvement opportunities.

- Explore contract opportunities with processors to secure price stability.

- Evaluate storage investment using expected price spreads and utilization rates.

- Adopt agronomic practices that balance yield gains with sustainable soil and water management.

Concluding observations on the future of potato profitability in Europe

Profitability in European potato production will increasingly reflect the ability to combine agronomic efficiency with value-chain integration and adaptive management. Farms that leverage technology, secure reliable market channels and respond to sustainability requirements are best positioned to preserve margins in the face of rising costs and climate uncertainty. Strategic investments in storage, varietal selection and cooperative structures can be pivotal, especially for producers in regions with limited access to processing infrastructure. Ultimately, a balanced approach — optimizing field performance while aligning to market signals and policy incentives — offers the strongest path to durable profitability across the diverse landscapes of Europe.